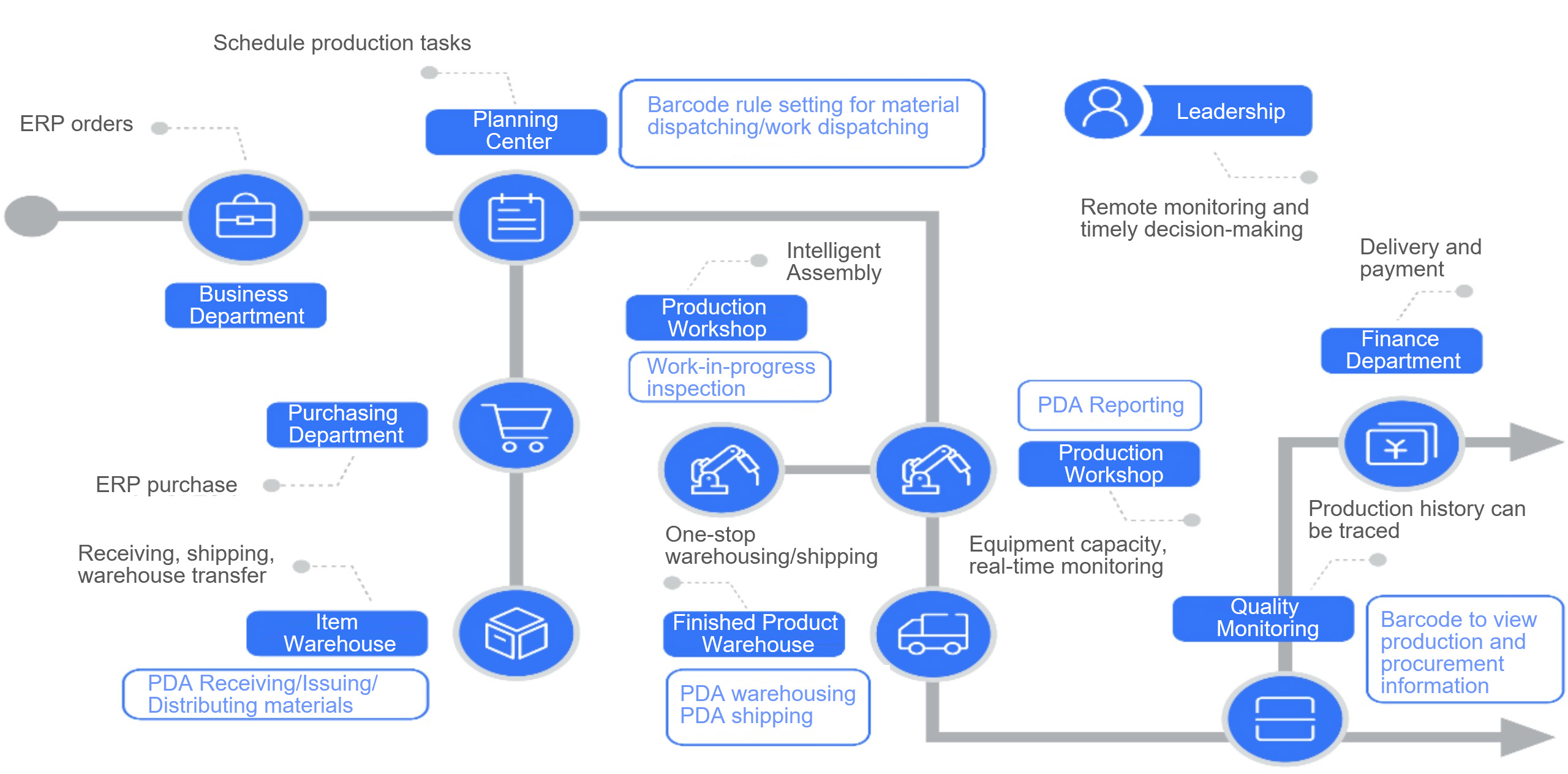

Intelligent manufacturing management solutions integrate contemporary advanced technologies, seamlessly integrate with intelligent logistics, WMS, and MES, and use big data analysis and IoT technologies to help manufacturing companies build efficient and intelligent operation models from high-level decision-making to middle-level control to grassroots operations. It promotes traditional manufacturing companies to achieve a management transformation from traditional to innovative, and a production transformation from manual to intelligent, and achieves a new breakthrough from "manufacturing" to "intelligent manufacturing".

Manufacturing Characteristics

⬛️ Difficulty in raw material management

Manufacturing products are iterating fast, with multiple varieties and small batches...high risk of inventory backlog; based on quality control, materials will be issued in the same batch, and there are many types of raw materials, which requires high requirements for material control management.

⬛️ Difficulty in delivery response

When receiving an order, you need to respond to the customer's feasible order delivery date. Because there are many factors involved and lack of decision-making information, it is impossible to make timely decisions on delivery evaluation.

⬛️ Difficulty in production process management

Production management is very cumbersome, involving production scheduling, order processing, progress monitoring, MTO management, alternative control, disassembly management, etc. For example, in material control, production process control is prone to errors.

Industry Demand

Solution Value

⬛️ Refined management: Improve enterprise execution

Refined management solutions start from visual decision-making, implement business analysis and management strategies into each link of refined control, and through a process-based execution system, enable each link of the enterprise to operate quickly and accurately, improve execution, comprehensively enhance the comprehensive strength of the enterprise, and make informatization the core competitiveness of the enterprise.

⬛️ System intelligence: comprehensively improve production efficiency

We integrate contemporary advanced technologies, seamlessly integrate with WMS and MES, and use big data analysis, Internet of Things technology, etc. to help companies create new "smart manufacturing" production management, improve production efficiency, and provide timely feedback on workshop dynamics, so that production progress is under control.

⬛️ Data visualization: driving management improvement

The visual management platform simplifies the complexities, takes orders as the core, establishes a "quantity, cost, profit and efficiency" data model, and guides manufacturing companies on the path of management and performance improvement.