In smart factories, the product life cycle traceability system is a key technology to achieve product quality control, production process optimization and consumer trust. Through information technology, the product can be fully traced and managed from raw material procurement to production, sales, and use.

System Introduction

The system is based on technologies such as the Internet of Things, big data and cloud computing to build a comprehensive, efficient and reliable product life cycle traceability platform.

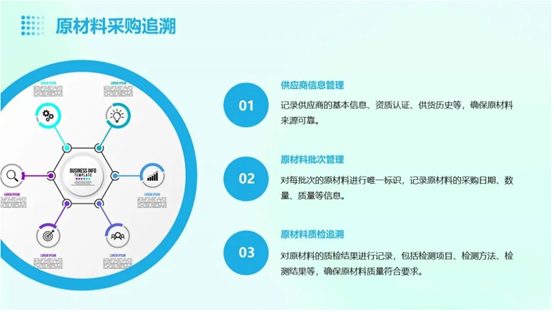

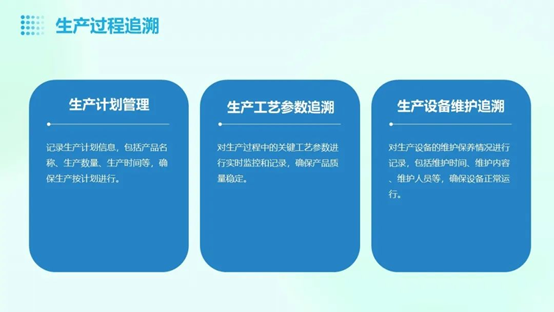

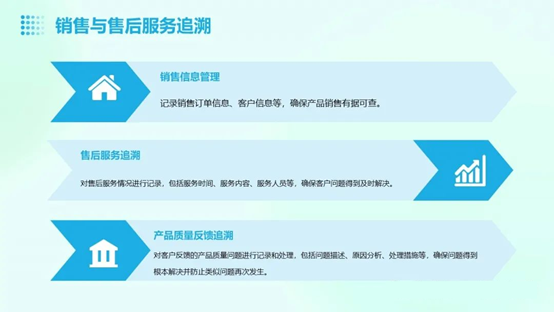

The core functions include: data collection and integration, traceability information query, production process monitoring, quality analysis and early warning, etc.

Key points of full life cycle traceability requirements

Advantage

1. The system supports multiple data interfaces and can be seamlessly connected with existing production management systems, sales management systems, etc. to achieve data sharing and collaborative work.

2. Through comprehensive traceability and management, timely discover and deal with potential quality problems, reduce product defect rates and recall risks.

3. Real-time monitoring of production site conditions, adjustment of production plans and resource allocation, and improvement of production efficiency and flexibility.

4. Provide consumers with accurate and transparent product information to enhance consumers' trust and loyalty to the brand.

5. Win market recognition with high-quality products and services, and enhance the company's competitive position in the industry.

Expected goals and benefits